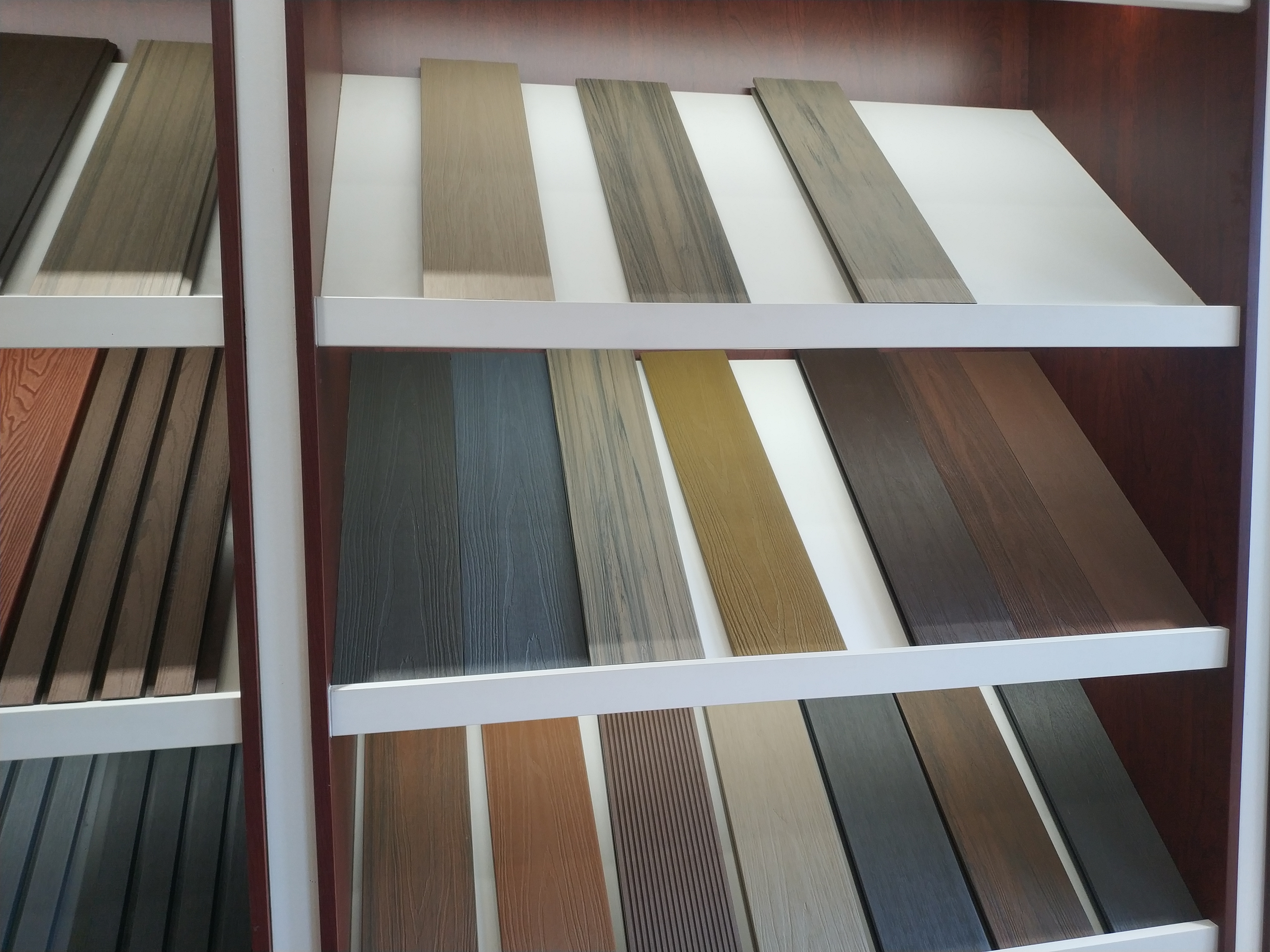

Wood plastic composite (WPCs) rudzi rutsva rwezvinhu zvakaumbwa zvakabudirira kumba nekune dzimwe nyika mumakore achangopfuura.Vanotaura nezvemahwendefa kana maprofayiri anogadzirwa nekushandisa polyethylene, polypropylene uye polyvinyl chloride pachinzvimbo chezvakajairwa resin adhesives, uye kusanganisa zvinopfuura 35% - 70% yehupfu hwehuni, goko remupunga, mashanga uye mamwe tsvina yechirimwa fiber kuita zvinhu zvitsva zvehuni, uye zvino kuburikidza ne extrusion, kuumba, jekiseni kuumba uye mamwe epurasitiki kugadzirisa maitiro.Inonyanya kushandiswa mukuvaka zvinhu, fenicha, logistics packaging uye mamwe maindasitiri.Purasitiki nehupfu yehuni inosanganiswa mune imwe chikamu uye yobva yaumbwa nekupisa extrusion, iyo inonzi extruded wood plastic composite plate.

Screw configuration inoita basa rakakosha mu extrusion process yehuni maplastic composite.Iyo inonzwisisika screw chimiro inogona kuderedza kukweshera pakati pesiruu uye huni fiber, kuburitsa kwakaringana kuveura uye kuparadzira kusanganisa, uye kuita iyo sisitimu yemidziyo ine huwandu hukuru hwehuni huni hwakagadzirwa zvakanaka plastiki.

Mold dhizaini uye kutonhora kupedzisa

Pamusoro pekuona shanduko yakatsetseka uye inoyerera kuyerera kweanomhanya dhizaini, matanda epurasitiki anoumbwa zvinhu zvine zvakakwirira zvinodikanwa zvekumanikidza kuvaka kugona uye kurongeka kwekudzora tembiricha.

Kuti uwane yakanaka faibha yekumisikidza uye mhando yechigadzirwa, zvinodikanwa kuve nechokwadi chekuti musoro wekufa une yakakwana yekumanikidza kuvaka hukuru uye kureba saizi chikamu, uye kutotora kaviri taper chimiro muchikamu chekumanikidza uye saizi chikamu.

Wood plastiki composite zvinhu zvine urombo hwekupisa conductivity, uye mazhinji ezvigadzirwa zvawo zvinhu zvine profiled, izvo zvakaoma kutonhodzwa uye kuumbwa, saka ivo vanonyanya kunyoroveswa nemvura.Mugero wekutonhodza uchagadzirwa zvine hungwaru kuti uve nechokwadi chekutonhodza zvakanaka.